When it comes to air tools and equipment, having the right air hose is critical to ensuring optimal performance and safety. There are many options on the market, and choosing the one that best suits your specific needs can be overwhelming. In this guide, we’ll explore the key factors to consider when choosing an air hose range and provide valuable insights to help you make an informed decision.

1. Understand the basic knowledge of air duct series

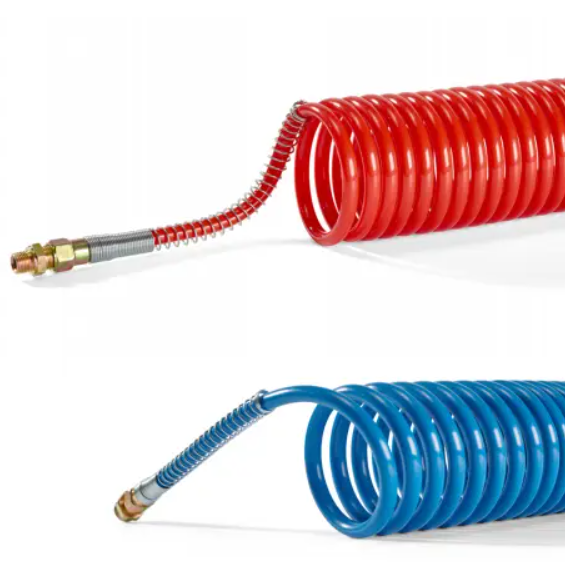

This series of air hoses is designed to deliver compressed air from compressors to pneumatic tools and equipment. They come in a variety of sizes, materials and configurations to suit different applications. The most common types of air hoses include rubber hoses, PVC hoses, hybrid hoses, and polyurethane hoses. Each type has its own unique characteristics and is suitable for specific purposes.

2. Factors to consider when selecting air hose series

- Size and Length: The diameter and length of the air hose range are important considerations. The larger diameter allows for higher airflow, while the longer hose provides greater coverage. Hose size and length must match the requirements of the pneumatic tool and distance from the compressor.

- Material: The material of your air hose range affects its flexibility, durability, abrasion resistance and kink resistance. Rubber hoses are known for their flexibility and durability, while PVC hoses are lightweight and cost-effective. Hybrid hose and polyurethane hose provide a balance of flexibility and durability.

- Pressure grade: The pressure grade of the air hose series indicates the maximum pressure it can withstand. Selecting hoses with a pressure rating that exceeds the maximum pressure of compressors and pneumatic tools is critical to ensuring safety and reliability.

- Temperature range: Consider the operating temperature range of the air hose range. Some hoses are designed to withstand extreme temperatures, making them suitable for outdoor or industrial applications.

- Fittings and Connections: Fittings and connection types on your air hose range should be compatible with your compressor and air tools. It is important to ensure connections are tight and leak-free to prevent air loss and maintain efficiency.

3. Choose the right air hose series for your application

- For general purpose use in workshops and garages, our range of rubber air hoses with medium pressure ratings and good flexibility are a reliable choice.

- For industrial applications requiring high airflow and abrasion resistance, a range of hybrid or polyurethane air hoses with high pressure ratings and durability are recommended.

- For outdoor or construction sites with frequent temperature fluctuations, PVC air hose series with wide temperature range and lightweight design are suitable.

In summary, choosing the right air hose range is critical to ensuring efficient and safe operation of your air tools and equipment. By considering factors such as size, material, pressure rating, temperature range, and fittings, you can select the most appropriate range of air hoses for your specific application. Investing in a high-quality air hose range not only improves the performance of your pneumatic system, it also helps create a safer, more efficient work environment.

Post time: Mar-12-2024